Affirming the importance of safety

Dredging activities can be risky operations with hidden dangers among heavy machinery. In response, the dredging industry proactively maintains a high level of safety standards. A representative of contractors in the dredging industry, IADC encourages its own members, as well as non-members participating in the global dredging industry, to establish common standards and a high level of conduct in their worldwide operations.

IADC’s members are committed to safeguarding their employees, continuously improving to guarantee a safe and healthy work environment and reducing the number of industry accidents and incidents to zero.

Recognising advancers of safety

IADC conceived its Safety Award to encourage the development of safety skills on the job and reward individuals and companies demonstrating diligence in safety awareness in the performance of their profession. The award is a recognition of the exceptional safety performance demonstrated by a particular project, product, ship, team or employee(s).

In total, nine submissions were received. Each one aims to improve routine processes and situations encountered in the dredging industry. The winner will be announced during IADC's Annual General Meeting in Barcelona, 13-15 September 2023.

Dredging contractor safety award submissions

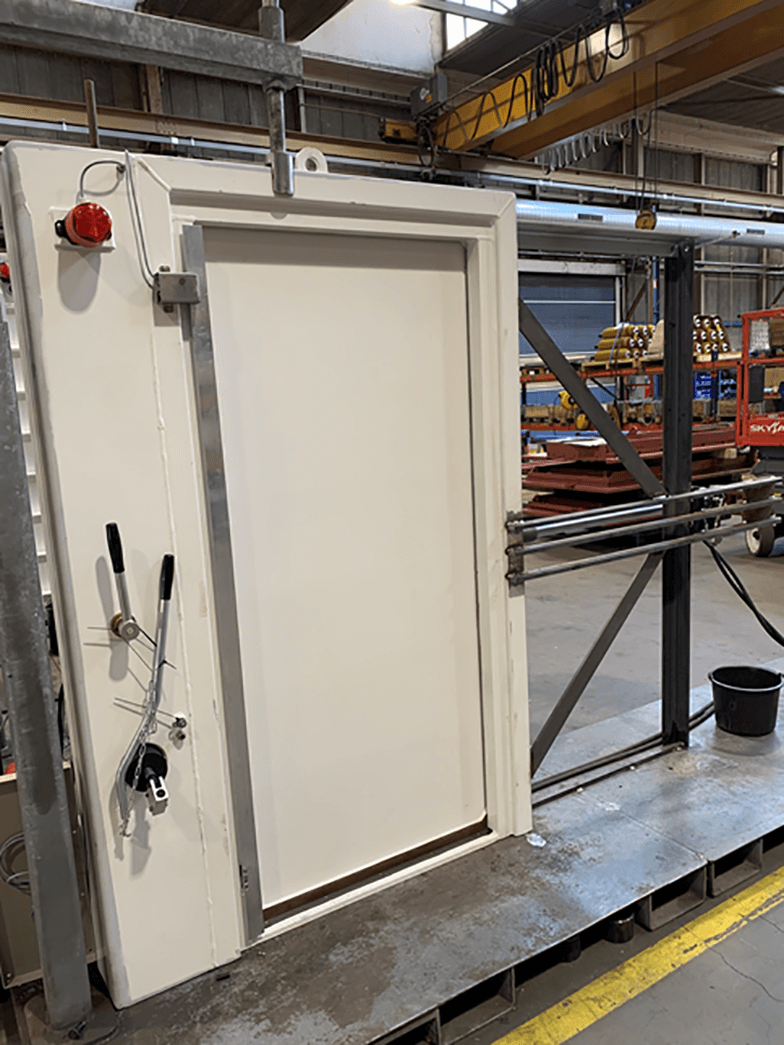

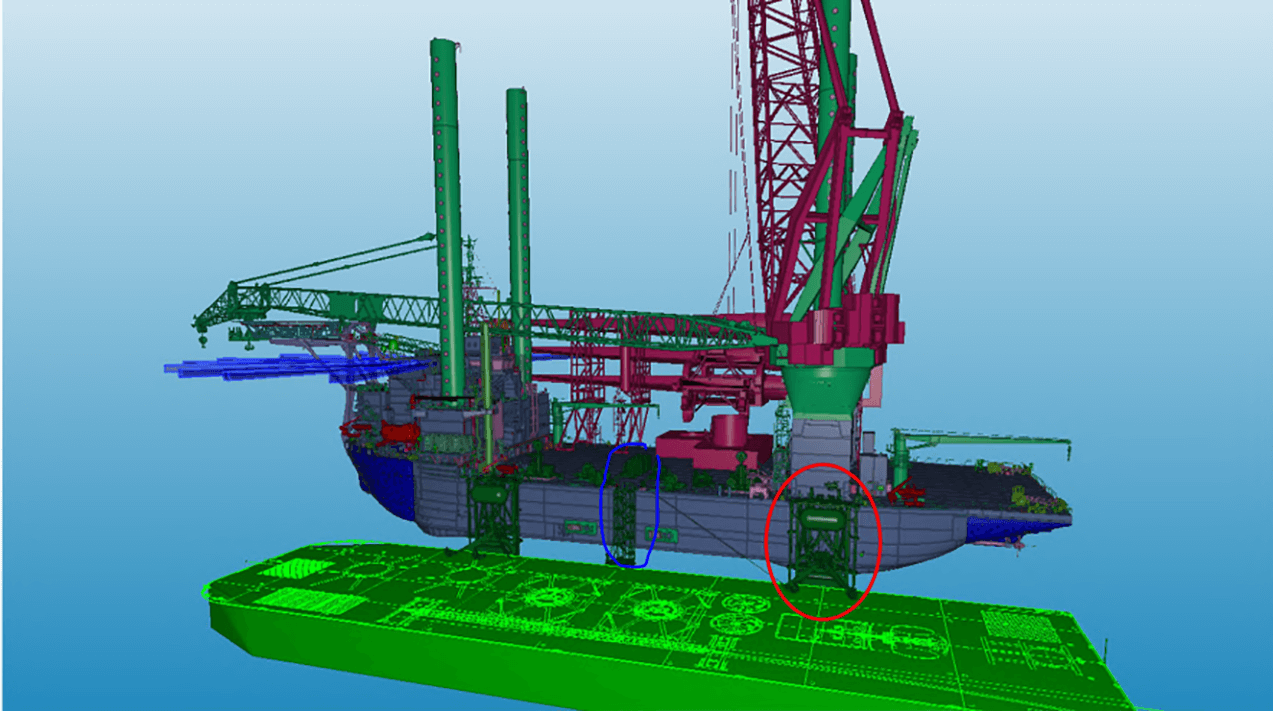

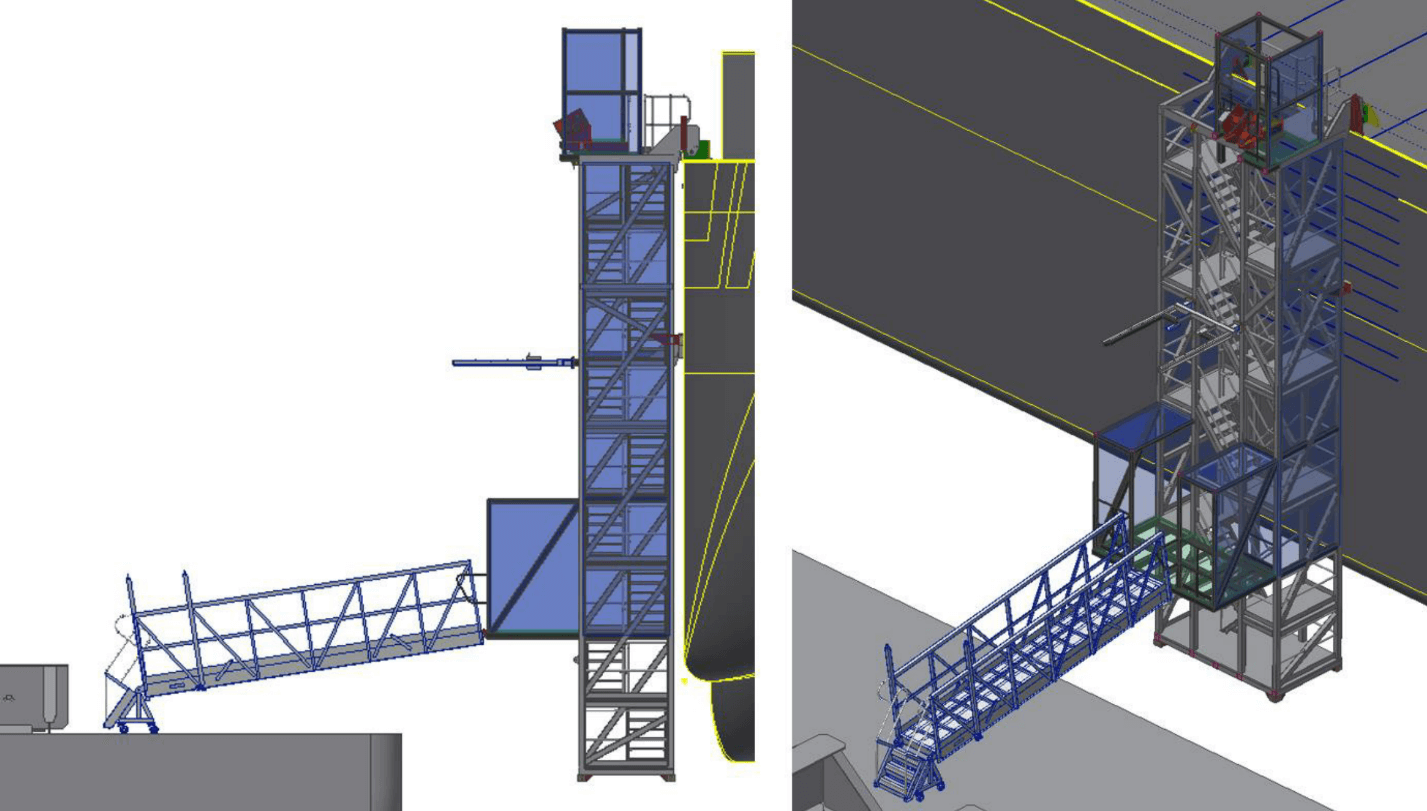

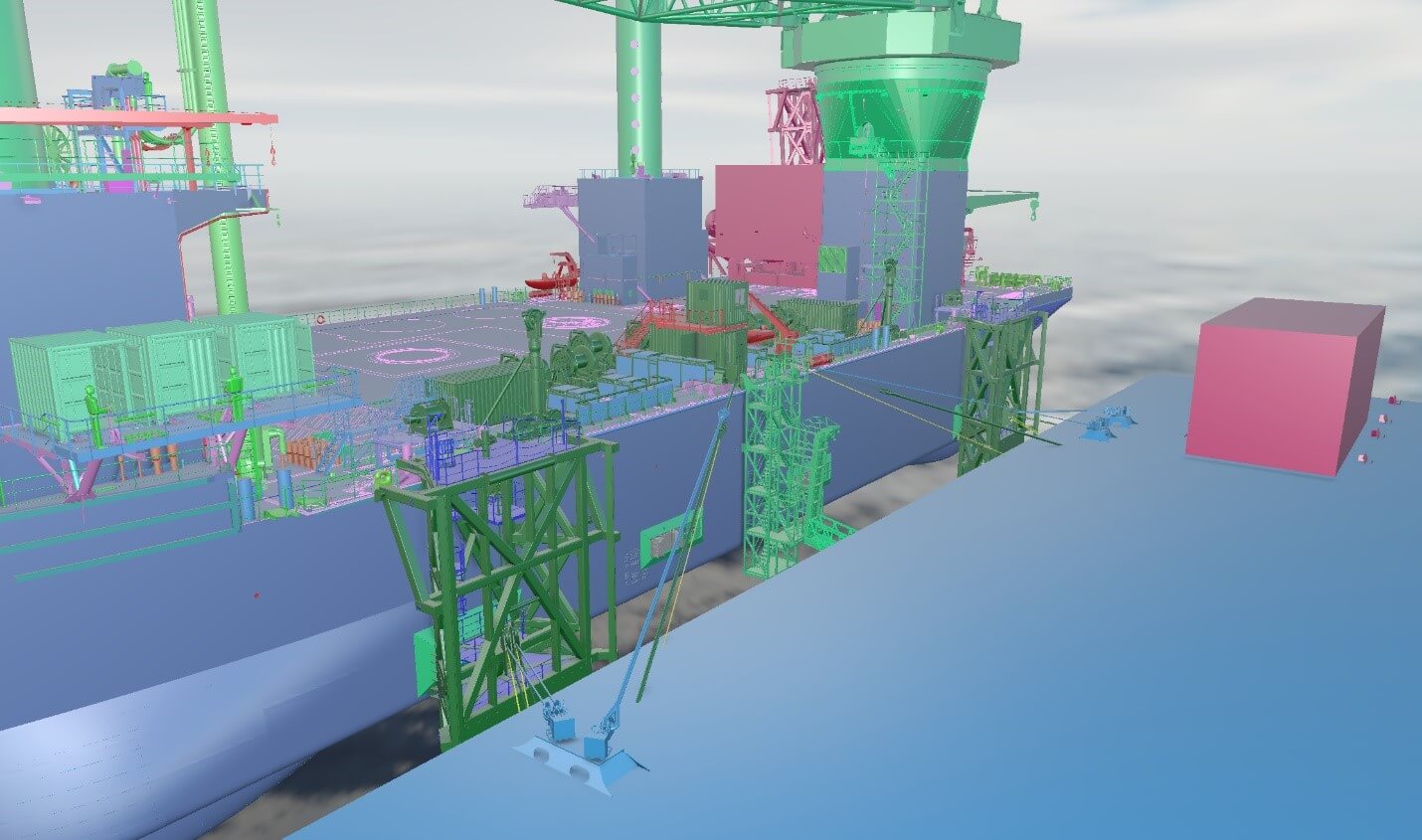

SAFETY BAR ON HYDRAULICALLY OPERATED WATERTIGHT SLIDING DOORS BY JAN DE NUL

In accordance with Safety Of Life At Sea (SOLAS), vessels are equipped with hydraulically operated watertight sliding doors (WTSDs). To prevent persons being crushed between a moving watertight sliding door and the doorframe, Jan De Nul is installing a safety bar on the doorframe of its hydraulically operated WTSDs. The safety bar is activated by pressure and upon activation the door reopens. The system is also equipped with an alarm so the bridge is alerted when the safety bar has been activated.

The first vessel equipped with this safety feature is the Trailing Suction Hopper Dredger Sanderus, Jan De Nul's fourth Ultra-Low Emission vessel (ULEv). By installing the safety bar, Jan De Nul is going beyond the standards set by the International Marine Organization (IMO), in that an additional safety layer is provided to protect personnel on board. The feature can be implemented on all dredging vessels with similar doors facing similar hazards.

Due to the nature of its design, the system makes the watertight door intrinsically safe without having to rely on human factors. The basic design makes it easy to install, maintain, use and prevent misuse (for example, using the safety bar to open the door instead of using the door handle).

During vessel familiarisation, crew are informed about the specific function of the safety bar and the consequences when it is activated. Additional specific familiarisation for bridge officers to deal with an alarm upon activation of the safety bar is also provided. In addition, posters and signs that include the safety bar are to be posted at every doorframe. The maintenance programme of the watertight sliding door is to be amended to include the monthly testing of the safety bar.

The installation of the safety bar also implies a deviation from the standard operating modes described in SOLAS, namely "local control" and "central close". A third operating mode is introduced, "central close with safety bar activated". Approval of relevant Classification Societies and Flag State to obtain an equivalence for the safety bar is required.